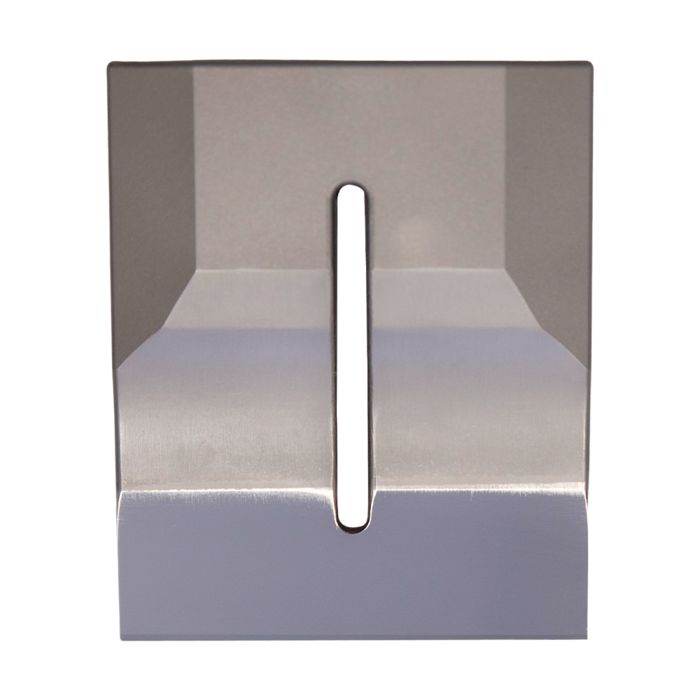

Cut edge

The perfect cutting result

The quality of the cutting edge is considerably better when using an ultrasonic cutting tool than with mechanical or thermal cutting processes. The high-frequency ultrasonic vibration reduces the resistance of the rubber material, making it easier to cut. This creates the perfect cutting surface for further processing.

Perfect Product

Components

Sonotrode

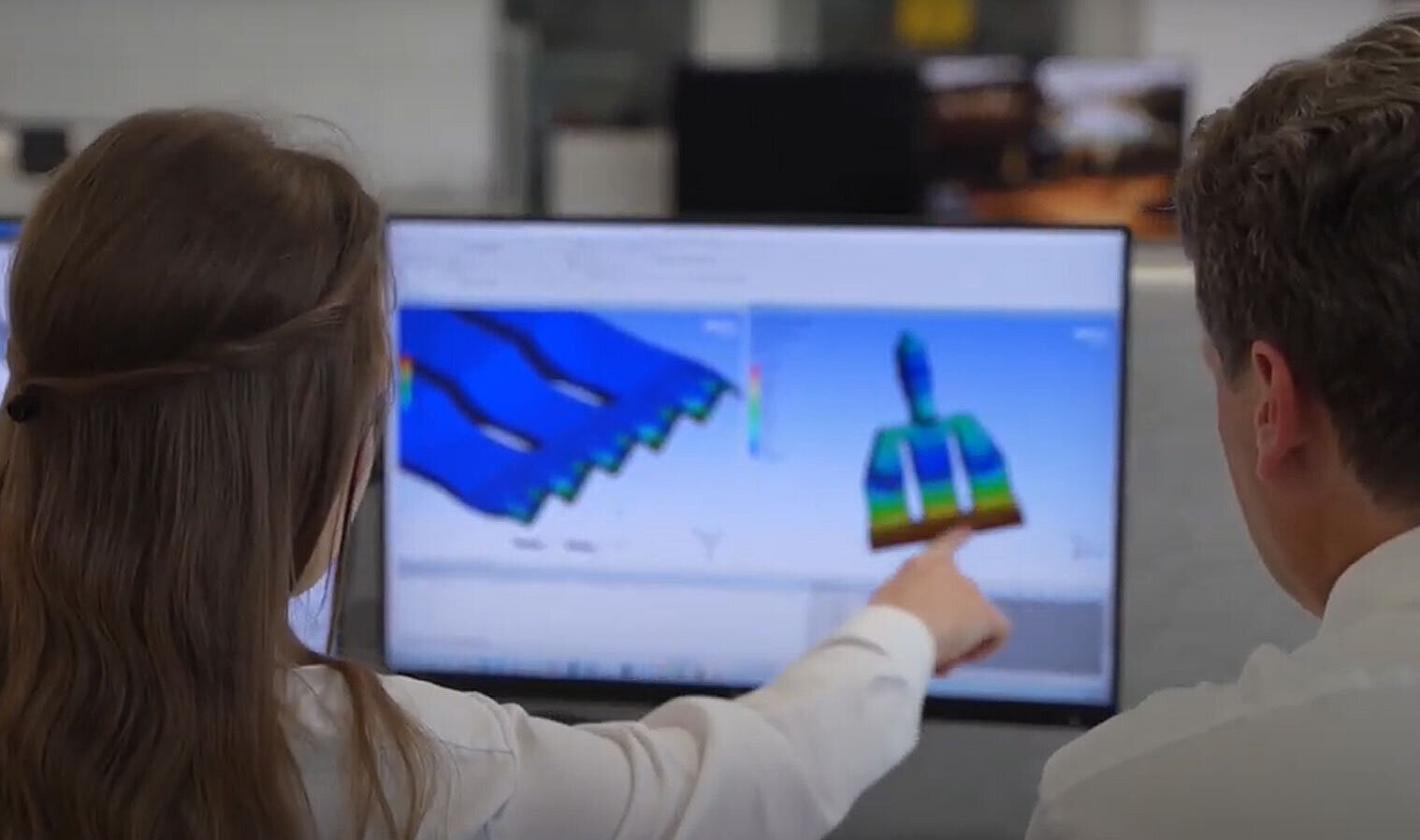

- Optimized sonotrodes calculated using the finite element method

- Auxiliary frequency analysis to prevent heat development

- Heat dissipation thanks to specially hardened steel

- Optional: Component cooling possible

5 × more durable and robust

The Herrmann hardened steel sonotrode is up to 5 times more robust than standard titanium sonotrodes. If required, it is also possible to rework the cutting edge – this extends the service life even more.

ULTRACUT-Generator

- USB and Ethernet interfaces

- Easy to enter process parameters, limits for power, time, energy

- System performance evaluation

- Generator with fieldbus interface for setting parameters

- DataRecorder data memory

- Graphical display of the cutting process by use of additional software (DIASim)

Why Herrmann?

Global partner with expertise

- Integration: Easy to integrate into existing production lines thanks to smart adapters. The simplest alignment options in the system.

- Process: Digital generator with limit monitoring and optional data recording, as well as visualization of the cutting process.

- Ingenious result: The optimized sonotrode surface design reduces resistance and thus prevents rubber burns and contamination on the cutting surface. Overall, significantly less contamination.

- Perfect product: Sturdy designs to prevent costly production down times. Optional system cooling to prevent the transfer of heat to the rubber material.

- Global service: Tech-Centers in over 20 countries guarantee local service and consistent quality with long-term spare parts availability.

Partner with Us

Contact our team to discover how our premium solutions can elevate the quality and effectiveness of your large-scale manufacturing. We look forward to hearing from you!