Weldable metals

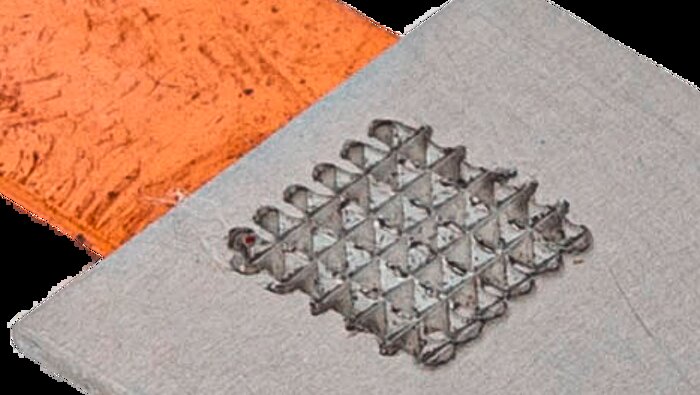

Ultrasonic welding is suitable for joining similar materials but can also be used for joining dissimilar materials. There are different welding techniques, for example, laser, gas, or ultrasonic welding. When metals are welded using ultrasonics, these are joined by the introduction of ultrasonic waves. This is a quick and especially energy-efficient process.

Ultrasonic welding technology for non-ferrous metals

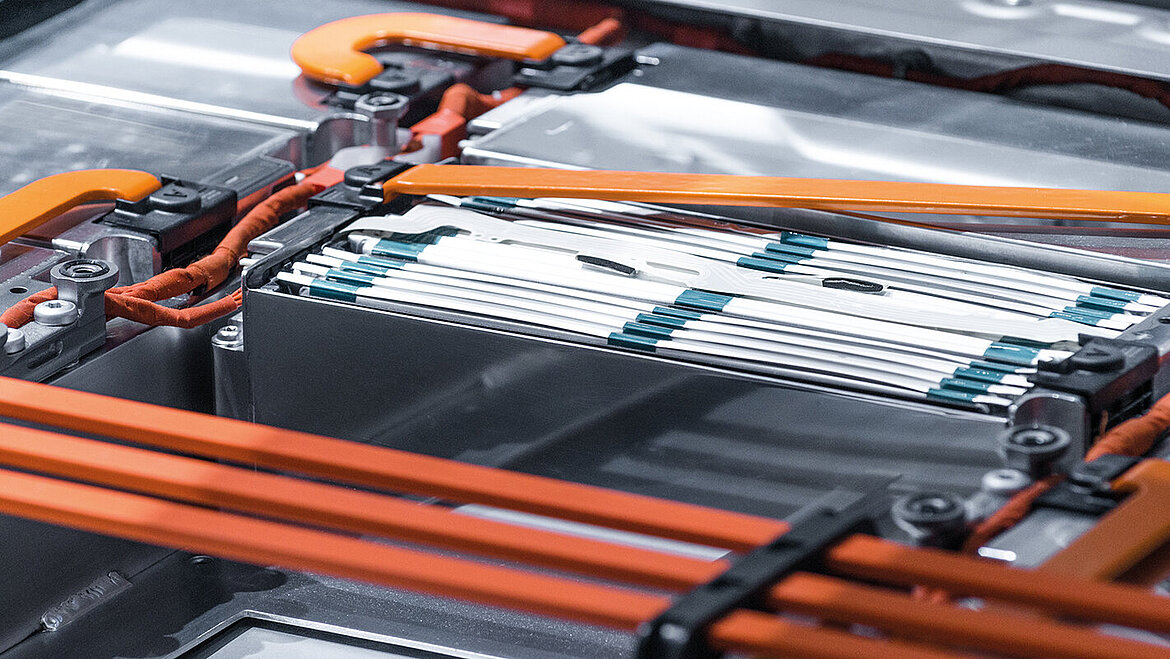

In ultrasonic welding, it is mainly nonferrous metals such as aluminum, silver, copper and nickel which are used, with copper-aluminum compounds accounting for 90% of the applications. This mainly involves welding batteries as well as cable and terminal connections in the electrical and automotive industries. Here, a highly precise and reliable welding method is crucial.

Nonferrous weldable metals are all pure metals apart from iron as well as alloys (compounds of various metals), which have an iron proportion of 50% of less. Pure ferrous metals are not used in ultrasonic welding.

Ultrasonic welding of aluminum

Given how important aluminum is to today’s industries, the ultrasonic welding process can be an ideal solution for a wide range of uses. For example, ultrasonic spot welding of aluminum and welding aluminum sheet metal are critical for automotive applications. Electronics benefit from the ability to join wires and other small components. Lithium-ion batteries commonly found in today’s hybrid and electric cars depend on strong bonds on aluminum components to ensure their reliability and durability. Ultrasonic welding improves the processes used in these industries thanks to its short weld time, high energy-efficiency, and the strength of the resulting bond.