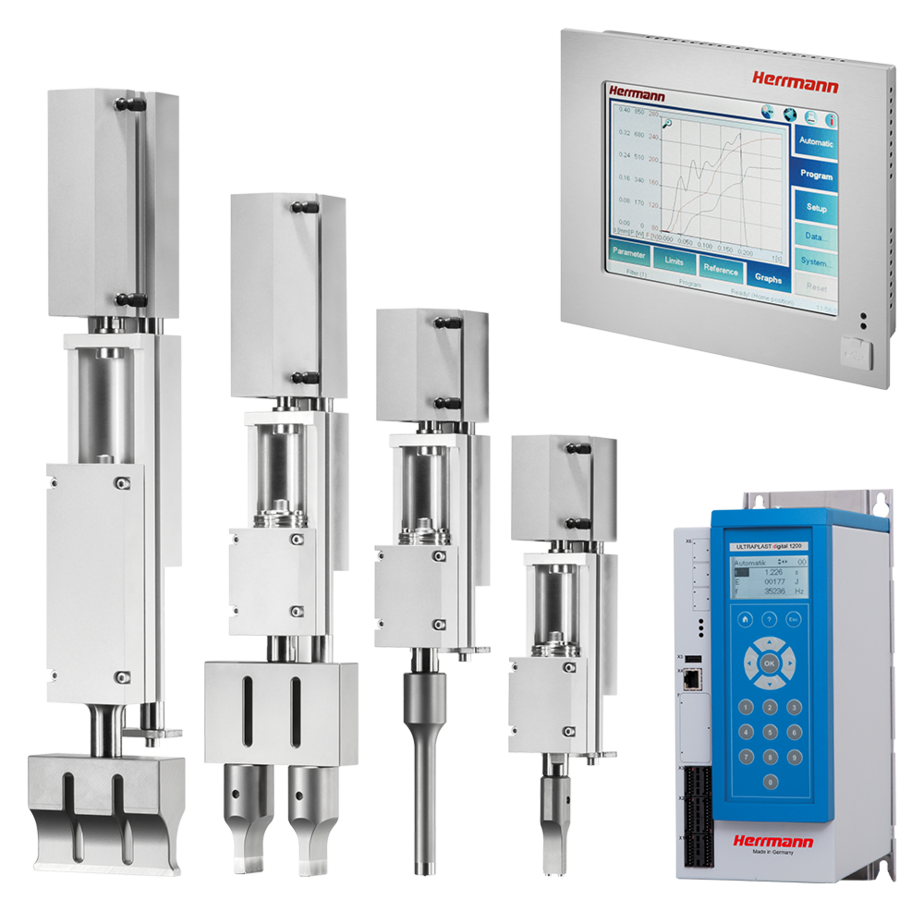

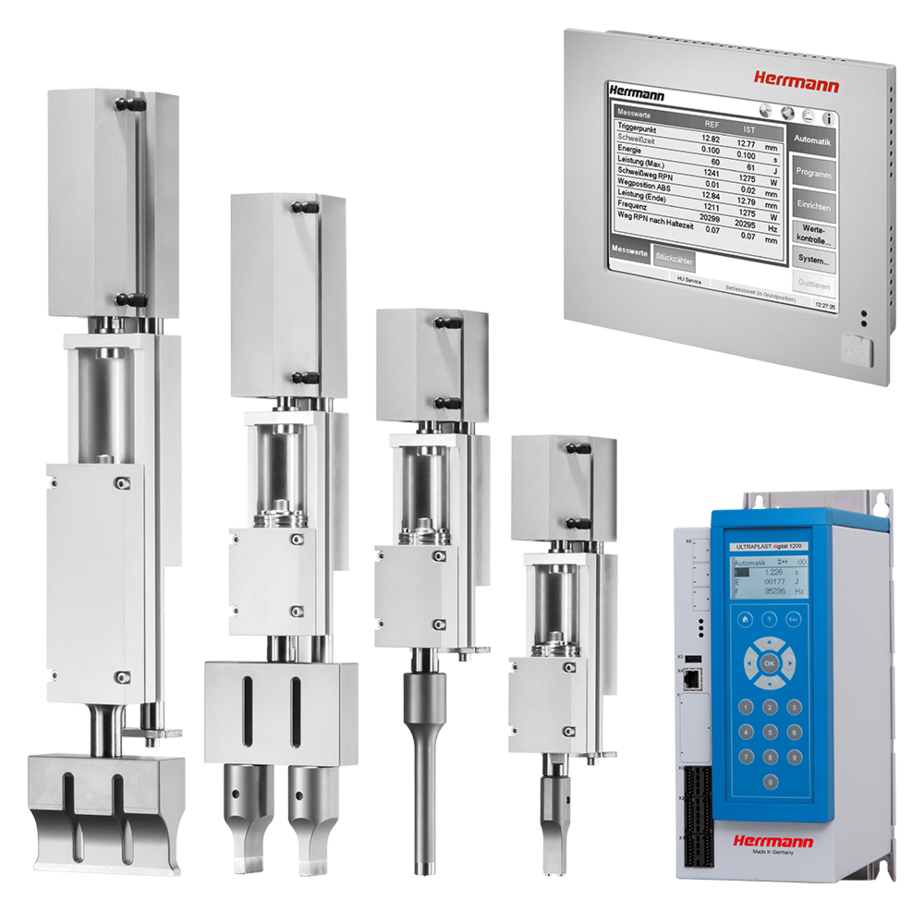

COMPACTLINE systems

Compact 35 kHz actuator product line of automated welding machines, when size and weight matters. Available as single components, for automation integration or in robotic welding automation systems for the flexible use of ultrasonic welding technology with high, repeatable weld results.

- 40 - 100 mm stroke length

- 16, 25 and 40 mm cylinder diameter

- 4 product types

In space-saving integration tasks in automation lines and in robot applications you can count on the familiar Herrmann ease of use and quality with these automatic welding machines. The VE COMPACTLINE VARIO actuator in combination with the weld process controller VARIO control provides excellent, reproducible weld results and visualization of the ultrasonic welding process supports parameter finding and recording for quality purposes. Proportional valve technology combined with appropriate position measuring systems complete this 35 kHz weld system with a generator power of 1,200 W.

- Flexible weld process controller: VARIO control

- Graphical weld process monitoring

- PropControl: proportional valve technology

- Application-oriented position measuring systems

- High degree of customization

| VE COMPACTLINE VARIO | 35 kHz |

|---|---|

| Generator power [W] | 1200 |

| Weld force min./max.* [N] *at 6 bar | 30 / 680 |

| Stroke [mm] | 40 / 100 |

| Outside dimensions (W x H x L*) [mm], *depending on type and stroke, without sonotrode | 56 / 75 / 264 - 417 |

| Operating device | 8,4" Touchscreen color |

| Operating modes | 5 |

| Application memories | 32 |

| Number of saved welds (weld data) | 100 per Memory |

| Control of auxiliary functions (optional) | max. 4 |

Even in this system class, a 5.7” touch screen is part of the system operation and process monitoring for operating convenience. Often, in automated 35 kHz applications, every millimeter of assembly space counts, every gram of weight saved in the weld system helps in the achievement of an optimal configuration of robotic arm welding machines. Individual weld forces can be easily programmed on the operating device using proven proportional valve technology.

- Compact and robust system structure

- Space-saving control solution: LOGIC control

- PropControl: proportional valve technology

- Position measuring system technology

- Operation via touch panel

| VE COMPACTLINE LOGIC | 35 kHz |

|---|---|

| Generator power [W] | 1200 |

| Weld force min./max.* [N] *at 6 bar | 30 / 680 |

| Stroke [mm] | 25 / 50 / 100 |

| Outside dimensions (W x H x L*) [mm], *depending on type and stroke, without sonotrode | 56 / 75 / 264 - 417 |

| Operating device | 5,7"-Touchscreen monochrome |

| Operating modes | 5 |

| Application memories | 50 per Memory |

| Control of auxiliary functions (optional) | max. 2 |

The most compact robotic welding automation solution Herrmann has to offer. When it comes to limited installation space and low weight, then you cannot beat this 35 kHz ultrasonic welding system. The digital high-performance generator offers a variety of possibilities for data exchange via Ethernet and optional fieldbus module. The SDM variant allows weld processes with position measurement and analysis. A useful supplement for higher quality requirements.

- Ultra-compact system structure

- System-integrated controller: SOLID control

- PropControl: proportional valve technology

- Position measuring system technology with SOLID SDM variant

- Various fieldbus modules (option)

| VE COMPACTLINE SOLID | SDM 35 kHz/ STE 35 kHz |

|---|---|

| Generator power [W] | 1200 |

| Weld force min./max.* [N] *at 6 bar | 30 / 680 |

| Stroke [mm] | 40 / 100 |

| Outside dimensions (W x H x L*) [mm], *depending on type and stroke, without sonotrode | 56 / 75 / 264 - 417 |

| Operating device | 128 x 64 Matrix Monochrome |

| Operating modes | 3 |

| Application memories | 8 |

Industry and production have a constantly increasing demand for complex and efficient automation systems and customized ultrasonic welding automation equipment. In line with demand, Herrmann offers the 35 kHz actuator product line with its own weld process controller as a complete integration solution. Whether it is a space-saving part of an automation line, or a light and compact end-of-arm solution on a multi-axis robot, this modular system offers many product configurations with suitable mounting and accessory possibilities. For builders of customized machines too, the VE COMPACTLINE, as an individual component that has been tried-and-tested for decades, offers a robust alternative to costly self-built solutions.