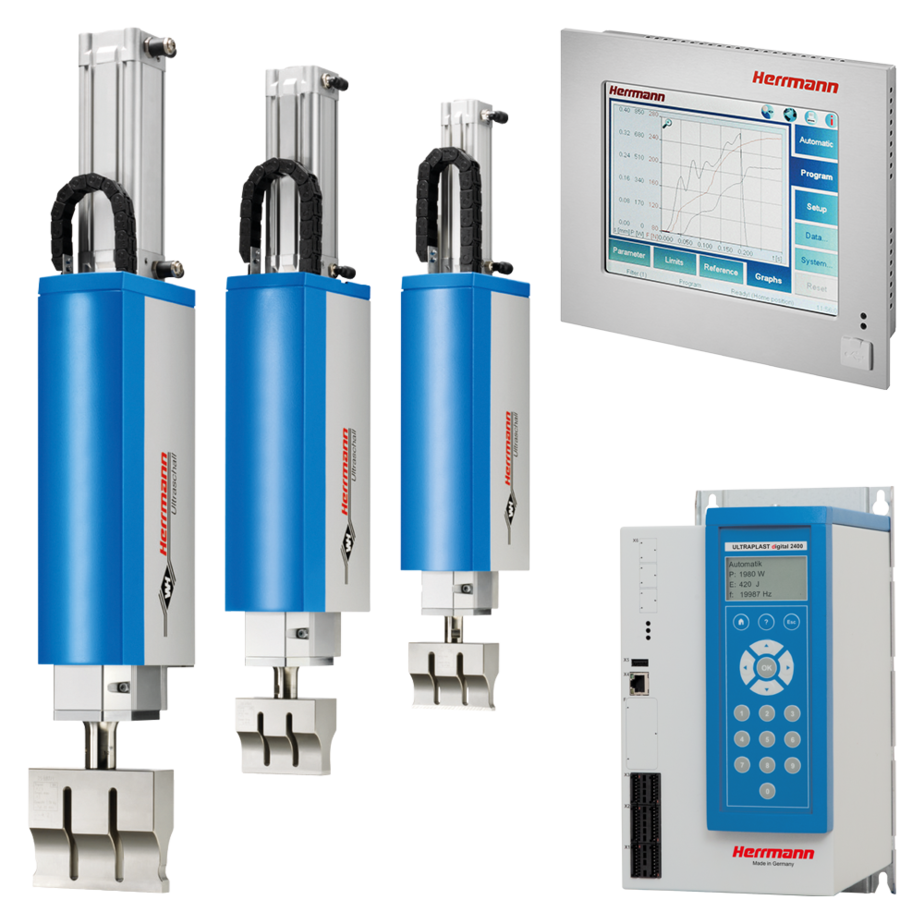

SLIMLINE systems

Standardized ultrasonic welding for semi-continuous operation in automation systems, maximum cycle rate – the typical requirement profile for an effective stack, also in packaging technology.

- 20, 30, and 35 kHz operating frequency

- 900 – 6,200 W generator power

- 10 – 2,490 N weld force

Fast movement sequences in the automation environment means money. The ultrasonic actuators VE SLIMLINE DIALOG with the pneumatic drive system HMC meet these requirements. The servo-pneumatic drive patented by Herrmann Ultraschall allows the stack to be freely positioned and ensures fast stroke motion, and its SoftTouch mode allows gentle contact with the plastic component to be joined in ultrasonic welding. The necessary weld forces and force profiles can be chosen and set as required. This protects sensitive weld joints and part surfaces.

- Weld process control: DIALOG control

- SpeedControl: freely programmable servo-pneumatic drive system HMC

- Reduced part-to-part times thanks to fast travel movements

- Pneumatics module in one assembly unit

- Interfaces for simple system integration

The latest generation of weld process software proves the innovativeness of Herrmann Ultraschall. DIALOG G4 stands for superlative software for the control and operation of the weld process, machine equipment, and up to six customized auxiliary functions. The intelligent process control reduces the reject rate, thus increasing efficiency.

- Five basic operating modes

- Two additional expert operating modes

- Process visualization

- Process-oriented user guidance

- Additional software packages

| VE SLIMLINE DIALOG | 20 kHz | 35 kHz |

|---|---|---|

| Generator power [W] | 2400 / 4800 / 6200 | 1200 |

| Weld force min./max.* [N] *at 8 bar | 30 / 2490 | 10 / 650 |

| Stroke [mm] | 150 | 100 |

| Outside dimensions (W x H x L*) [mm] *without sonotrode | 105 / 170 / 696 | 90 / 135 / 523 |

| Operating device | 15" Touchscreen color | 15" Touchscreen color |

| Operating modes | 7 | 7 |

| Application memories | 1000 | 1000 |

| Number of saved welds (weld data) | 300 pro Memory | 300 pro Memory |

| Control of auxiliary functions (optional) | max. 6 | max. 6 |

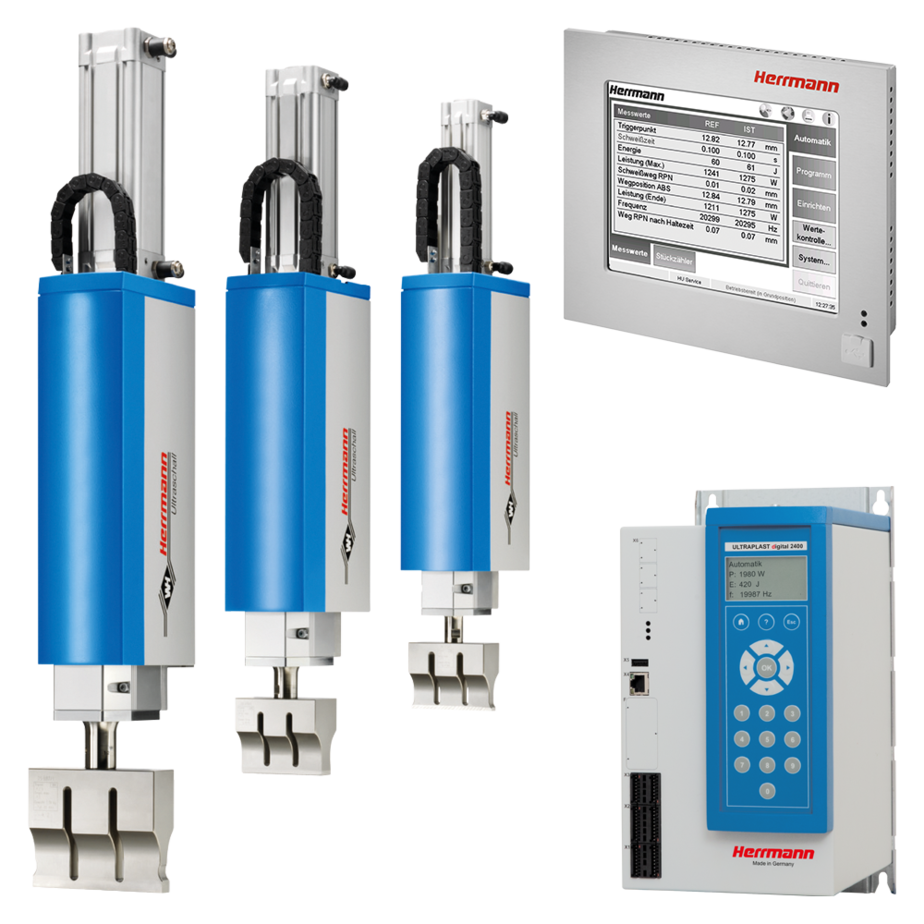

The actuator VE SLIMLINE VARIO offers the most flexible platform for automation tasks. Suitable generator power levels of up to 6,200 Watt in 3 different weld frequencies, strokes optimized to the cycle time, and a very wide range of weld force gradations can be configured depending on the weld application. Reliable proportional valve technology from Herrmann comes as standard as does the use of highly precise position measuring systems. The VARIO Control weld process controller provides support in parameter finding and quality recording during production with a visualization of the ultrasonic welding process.

- Intuitive weld process controller: VARIO control

- graphic recording of the weld process

- PropControl: proportional valve technology

- application-oriented position measuring systems

- process-optimized weld force ranges

The weld process software of the VARIO series underlines the quality standards of the plastic industry. The graphical display of the joining curve supports the users in the finding of parameters and recording of quality during production. The unicode compatibility of the control panel allows menu navigation in 14 languages.

- Five operating modes

- Process visualization

- Process-oriented user guidance

- Additional software packages

- Weld force switch-over

| VE SLIMLINE VARIO | 20 kHz | 30 kHz | 35 kHz |

|---|---|---|---|

| Generator power [W] | 2400 / 4800 / 6200 | 1800 | 1200 |

| Weld force min./max.* [N] *at 8 bar | 30 / 2490 | 30 / 1500 | 10 / 650 |

| Stroke [mm] | 25 / 50 / 100 / 150 | 25 / 50 / 125 | 25 / 50 / 125 |

| Outside dimensions (W x H x L*) [mm] *without sonotrode | 105 / 170 / 696 | 98 / 155 / 602 | 90 / 135 / 548 |

| Operating device | 8,4" Touchscreen color | 8,4" Touchscreen color | 8,4" Touchscreen color |

| Operating modes | 5 | 5 | 5 |

| Application memories | 32 | 32 | 32 |

| Number of saved welds (weld data) | 100 pro Memory | 100 pro Memory | 100 pro Memory |

| Control of auxiliary functions (optional) | max. 4 | max. 4 | max. 4 |

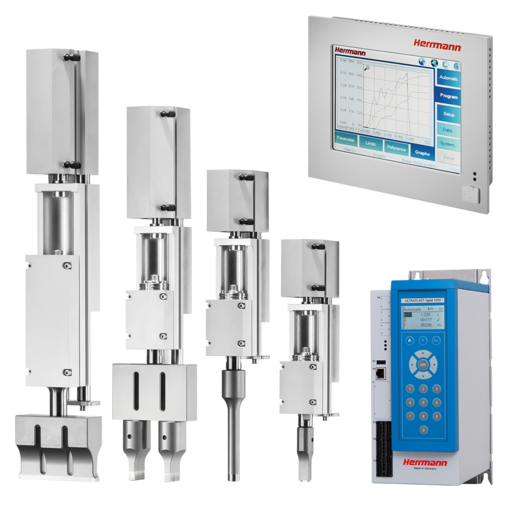

Repeatable weld results in automation are delivered thanks to a solid console structure with precision guiding rails and the indispensable proportional valve and position measuring technology which Herrmann provides as standard in this system class. The operation of the ultrasonic welding system and monitoring of the weld process are carried out on a compact 5.7” touch screen, which can be integrated in the automation line in a space-saving way.

- Slim and solid system structure

- Integration-friendly controller: LOGIC control

- PropControl: proportional valve technology

- Position measuring system technology

- Clearly laid out touch panel

LOGIC control – the entry-level class with unicode-compatible touch panel. Password protection and part counters also come as standard. A clearly laid out 5.7” touch screen allows simple parameterization and control of the weld process.

- 5 operating modes

- Operating device 5.7” touch screen monochrome

- 16 application memories

- 50 saved welds per memory

| VE SLIMLINE LOGIC | 20 kHz | 35 kHz |

|---|---|---|

| Generator power [W] | 1600 / 2400 / 4800 / 6200 | 1200 |

| Weld force min./max.* [N] *at 8 bar | 70 / 2350 | 30 / 590 |

| Stroke [mm] | 25 / 50 / 100 | 25 / 50 / 100 |

| Outside dimensions (W x H x L*) [mm] *without sonotrode | 105 / 107 / 696 | 90 / 135 / 548 |

| Operating device | 5,7"-Touchscreen monochrome | 5,7"-Touchscreen monochrome |

| Operating modes | 5 | 5 |

| Application memories | 50 pro Memory | 50 pro Memory |

| Control of auxiliary functions (optional) | max. 2 | max. 2 |

Depending on the applications to be solved, Herrmann offers a choice between two system variants: VE SLIMLINE SOLID STE and VE SLIMLINE SOLID SDM with position measuring system. Both variants are equipped with proportional valve technology and digital high-performance generators. These basic automated welding systems already fulfill all the necessary functions for ensuring 100% quality welding. The compact design of the actuators and generators allows maximum ultrasonic quality with a minimum space requirement.

- Compact, slim design

- System-integrated controller: SOLID control

- PropControl: proportional valve technology

- System variant with position measuring system (SOLID SDM)

- USB interface for data exchange

Ultrasonic welding is reduced to the essentials with SOLID control. The SOLID control STE is the basic model with the three weld modes time, power and energy. The SOLID control SDM is additionally equipped with the distance and depth operating modes.

- 3 operating modes: time, power, energy in the controller SOLID control STE

- Plus 2 operating modes: distance and depth in SOLID control SDM

- Operation via keypad with unicode-compatible matrix display

- 8 application memories

| VE SLIMLINE SOLID | SDM 20 kHz | SDM 35 kHz | STE 20 kHz | STE 35 kHz |

|---|---|---|---|---|

| Generator power [W] | 900 / 1600 / 2400 / 4800 / 6200 | 1200 | 900 / 1600 / 2400 / 4800 / 6200 | 1200 |

| Weld force min./max.* [N] *at 8 bar | 70 / 2350 | 30 / 590 | 70 / 2350 | 30 / 590 |

| Stroke [mm] | 50 / 100 | 50 / 100 | 50 / 100 | 50 / 100 |

| Outside dimensions (W x H x L*) [mm] *without sonotrode | 105 / 170 / 696 | 90 / 135 / 548 | 105 / 170 / 696 | 90 / 135 / 548 |

| Operating device | 128 x 64 Matrix Monochrome | 128 x 64 Matrix Monochrome | 128 x 64 Matrix Monochrome | 128 x 64 Matrix Monochrome |

| Operating modes | 5 | 5 | 3 | 3 |

| Application memories | 8 | 8 | 8 | 8 |

Herrmann offers a wide variety of actuators, including all characteristics and equipment features of the proven series machines. Particularly impressive aspects of the actuators include their compact design and robust ultrasonic components. Whether you need high or low weld forces, the Herrmann Ultraschall modular system offers a comprehensive integration package for machine builders and automation specialists. Each complete system forms a functional unit, which facilitates integration and start-up. Ultrasonics with a wide variety of accessories and options.

Our automatic welding systems use the latest in technology to allow for increased productivity. Customers can count on our products to deliver consistently repeatable results throughout their processes. This in turn leads to high levels of quality and consistency across their product lines, improving customer satisfaction and reducing waste in their production. For these and many more reasons, our automatic welding equipment is found in facilities across multiple industries.

Individual system additions

- Individual equipment design

- Adjustment and assembly system

- Mounting solutions for operating monitor

- Additional software packages for quality assurance

- Auxiliary tools

- Fieldbus interface

- ULTRACARE spare parts packages